Yield Management System

✔ Web-based architecture allowing multiple users to remotely log in and access the system simultaneously via the network domain, enabling them to grasp production status anytime, anywhere.

✔ Production history data statistical report output.

✔ Real-time status monitoring of defects during equipment production.

✔ Integration of defect map overlay and defect type code identification functions.

✔ Ability to collect AOI defect image data for offline defect observation and measurement.

✔ Integration with AI for big data analysis and feedback to production equipment for early warning of production anomalies.

✔ Manual judgment and classification of defects by personnel.

Share:

Applied Field

Semiconductor Industry

Panel Industry

Printed Circuit Board (PCB) Industry

Features

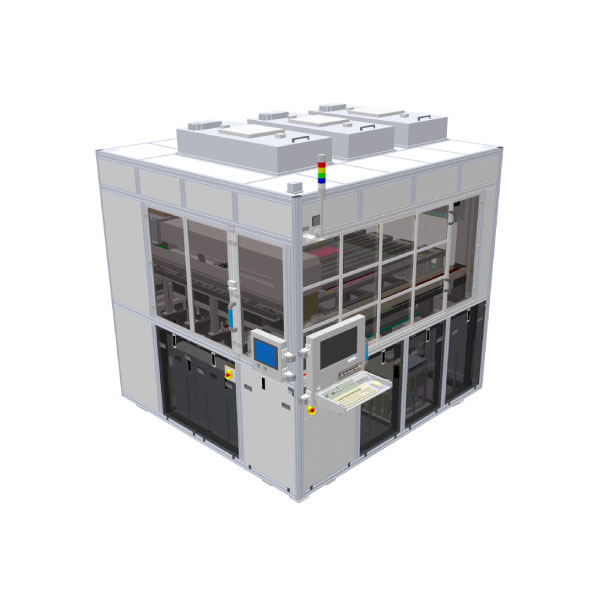

Combining years of experience in the AOI industry and defect detection/metrology, FAVITE has developed the YMS Yield Management System. Addressing real customer needs, it integrates massive amounts of AOI data to build a complete product production history. The simple and easy-to-use user interface allows managers to grasp product quality at any time. Through real-time monitoring and analysis tools, it quickly identifies the root causes of process anomalies and implements improvements.

Features:

✔ Web-based architecture allowing multiple users to remotely log in and access the system simultaneously via the network domain, enabling them to grasp production status anytime, anywhere.

✔ Production history data statistical report output.

✔ Real-time status monitoring of defects during equipment production.

✔ Integration of defect map overlay and defect type code identification functions.

✔ Ability to collect AOI defect image data for offline defect observation and measurement.

✔ Integration with AI for big data analysis and feedback to production equipment for early warning of production anomalies.

✔ Manual judgment and classification of defects by personnel.

Contact